Knitting Machines That Deliver Quality & Efficiency

Affordable, durable, and built for small and large-scale production. We offer reliable alternatives to industry giants like IMS Textiles.

Key Benefits

Industry-Leading Precision

Perfect stitches, every time

Built for Volume

Scale without compromise

USA-Based Support

Only brand to provide Local assistance

Effortless Reliability

Low maintenance with ease of operation

product detail

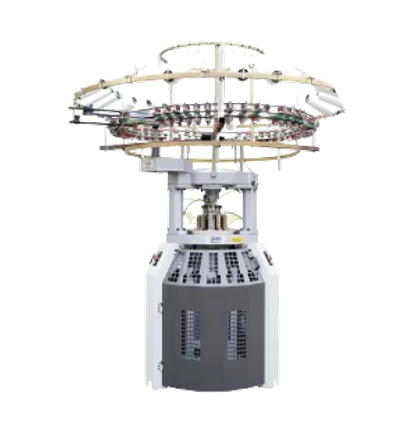

Hat And Scarf Knitting Machine

- Fully automatic and computer-controlled

- Knits a seamless hat in ~3 min, scarf in ~7 min

- 9″ cylinder with 144–360 needles for versatile designs

Automatic Knitted Hat Overlock Sewing Machine

- omputer‑controlled overlock finish for knitted hats

- Processes ~400–500 beanies/hour

- Effective sewing range 300 × 300 mm, max speed 3500 rpm

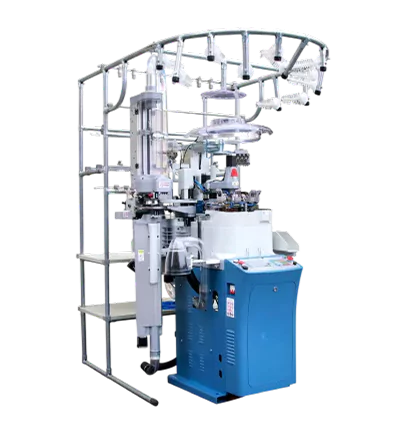

Rib Knitting Machine

- Seamless headwear with all‑yarn support

- Auto yarn feeding, stop-motion & oiling

- High-speed precision with touchscreen control

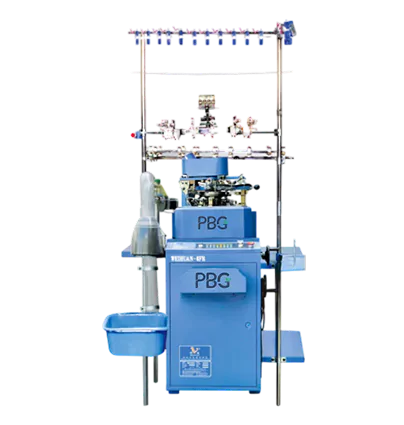

PBG A6 Auto Linking Machine

- ½″ barrel, 96–200 needles, max 350 RPM

- 9 pneumatic + 6 color shuttles (up to 13-color jacquard)

- Dual-feed system for heels, jacquard, 180° and 3D socks

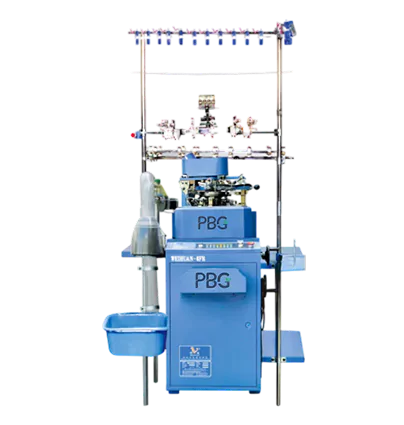

PBG 3.5 Computerized Terry/Plain Socks Knitting Machine

- ½″ cylinder, 42–220 needles; runs at 230–350 RPM

- One or two feeds, 6 actuators, 13 shuttles & 8 yarn fingers

- Plain, terry, or dual-use socks; 3‑phase power (220/380/415 V)

PBG-B6R Any Terry Socks Knitting Machine

- 3½″ cylinder, 42–240 needles; body 200–350 RPM, heel 200–280 RPM

- 7 actuators, 17 yarn shuttles & 9 pneumatic fingers with auto feeding

- Plain, terry, or combo sock options; supports 3‑phase 220/380/415 V power

Side-by-Side Feature Comparison

|

Others | |

|---|---|---|

| USA-Based Support |

|

|

| On-Site Training |

|

|

| Financing Options |

|

|

| Easy Learning Curve |

|

|

| Parts Availability |

|

|

| Customization Options |

|

|

| Durability & Longevity |

|

|

| Production Speed |

|

|

| Ongoing Training & Support |

|

|

| Software & Technology |

|

|

FAQs

PBG Care offers a diverse lineup of knitting machines, including:

- Hat & scarf knitting machines—ideal for seamless accessories

- Automatic hat overlock sewing models

- Rib knitting machines

- Computerized sock knitting machines such as PBG A6 auto linking and PBG-B6R Terry/Plain models.

Our machines—which include semi- and fully-automatic variants—operate continuously and at high speed (e.g., 120 RPM for hat/scarf machines), enabling batch production like one hat in ~3 minutes and one scarf in ~7 minutes. This dramatically reduces production times versus manual methods.

Circular knitting machines allow continuous, seamless fabric creation (e.g., socks, hats) while slashing labor and energy costs. They produce highquality, uniform fabrics with minimal waste.

Electronic knitting machines provide programmable versatility, fast production cycles, and seamless garment output—meeting the U.S. demand for sustainable, on-demand, and domestic manufacturing.

Despite higher upfront costs, auto knitting machines save on labor, reduce material waste, enhance product quality, and offer long-term cost benefits

While U.S. knitting machine demand dipped in 2024 (to ~30K units), forecasts show steady growth: a +3.8% CAGR in volume and +3.9% in value through 2035. Meanwhile, global knitting-machine investments are projected to reach $9B by 2032.

Our knitting machines offer precise tension control and automated density adjustment (e.g., via stepper motors), ensuring consistent stitch accuracy— critical for thermal wear and accessories.

Absolutely. Models like rib and hat/scarf machines offer flexible production suitable for boutique and small-to-mid production. Combined with 24/7 support, financing options, and training, they’re perfect for startups or scaling operations.

Computerized and circular knitting machines reduce fabric waste, eliminate seams, and require less energy—aligning with growing eco-conscious manufacturing trends.

We offer U.S. customer service, spare parts, remote and onsite technical support. We also help organize demos at shows (e.g., Impressions Expo, Long Beach) to connect buyers with the best machine for their needs.